G'day viewers

Here are some photos I took a while back of the corrosion caused by ballast cement.

I thought it may have been due to the flux I use to solder, but because it has only appeared where I used Chuck's ballast cement, I have to blame that. All the other parts of the layout are unaffected.

I don't know what's in it exactly, but the rail has adopted a very un-protoypical filigree look (nickel-silver oxide must look a lot like copper oxide).

Going to be a pain in the bum cleaning it off the finer details of pointwork and rodding.

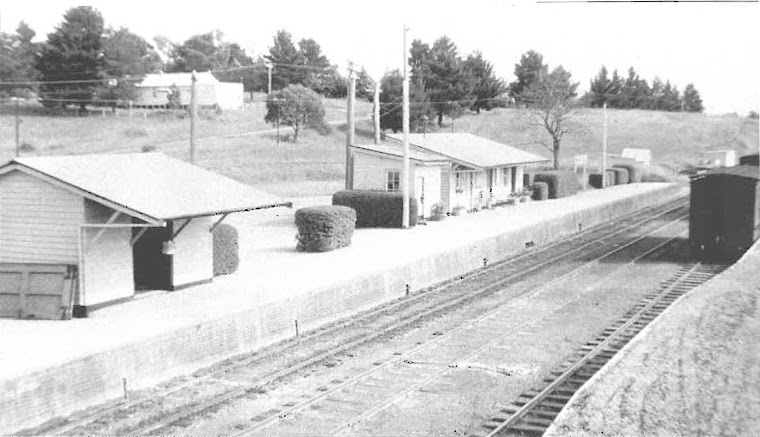

Here is the culprit.

Has anyone else had this experience?

Cheerio

James

Well that would suck immensely!! What's in the glue, surely its PVA based?

ReplyDeleteCheers,

Rob

I don't know the recipe, Rob. I think the adhesive is pva or latex based mixed with some kind of wetting agent. Obviously not pH balanced though!

ReplyDeleteThe green patina is because nickel silver is 50 - 80% copper. See https://en.wikipedia.org/wiki/Nickel_silver

ReplyDeleteProbably the ph of the glue/water/detergent mixture was in a range to cause the copper oxidation. This happened recently on some ballasting done on our exhibition layout. That was the first time I have ever seen it happen. Your example is the second.

James

ReplyDeleteWhile this is in hindsight, over the years I have resisted buying anything deemed as specialised type glues for trackwork & used to stick to the old tried & true diluted PVA mix.

I have also used a product purchased in Sydney from Paint Wholesalers at West Ryde called Perma Plastik clear paint extender again diluted in a 4:1 mix, this gives the best result as it does not dry to any sort of waxy look that can affect PVA mixes. along with changing the ballast to a somewhat darker colour.

I have also used it for setting static grass to the layout as well. Only issue with it is that if separates in the tin & needs a fair bit of mixing, through before doing a brew, & only doing enough for the job intended. The best part is that it dries perfectly matte.

I certainly hope the track can be cleaned up without any ongoing issues.

Cheers

Col

James, just a bit of a further comment. Have you been in touch with the glue manufacturer to get his comments? He may be able to help with suggestions or better still a solution.

ReplyDeleteThe problem certainly is visible on the rail heads as no doubt those areas are not painted, but the glue would have got on the sides & could it also get into the paint & affect it as well? which really is something for a later concern.

While it does seem strange to market a product that could cause this problem after all a ballast glue has a reasonable chance of getting on the rail sides, the problem is to fix it.

I would try Metholated Spirits with a course cloth to rub over the areas, but also use a track cleaner, my favourite being the Fleischman brand block, looks like the Peco but larger & seems much finer & certainly cleans better with less effort than the Peco one.

Thanks all for your comments. Sounds like the perma-plastik is worth a try. I've also used matte-medium in dilute pva to tone down the waxy lustre for attaching static grass, flock, etc

ReplyDeleteMetho for cleaning is also a good idea.

Although it's a pain, I'm not too concerned about having to re-do part of the trackwork if that's what it takes. This particular module was always about having a go and having the courage to make a few mistakes along the way.

This comment has been removed by the author.

ReplyDeleteA case of the solution being the problem.

ReplyDeleteSorry, couldn't resist

Cheers

John

Boom boom! Very good John! :-)

DeleteJames, I have had the same problem, as with others I know. I put it down to the Kitchen detergent used to allow better spread. As it is only in spots where it happens I think it is the heavier mix where the detergent is not mixed properly in the bottle.

ReplyDeleteMaybe a bit late to comment. I had the same issue on my home layout in 1985. It was suggested by a geologist in our club, that iron pyrites in the ballast will react with PVA glue to form a chemical blackener for nickel silver. The ballast I used was sifted by myself from roadside blue-metal (yes I was cheap then - still am). I lived with it, but the rail could have been painted.

ReplyDelete